All tube-and-clamp scaffold components are vital for proper weight distribution, stability and safety. Each scaffold component contributes to the structure’s ability to bear heavy loads, support workers, withstand wind and remain secure.

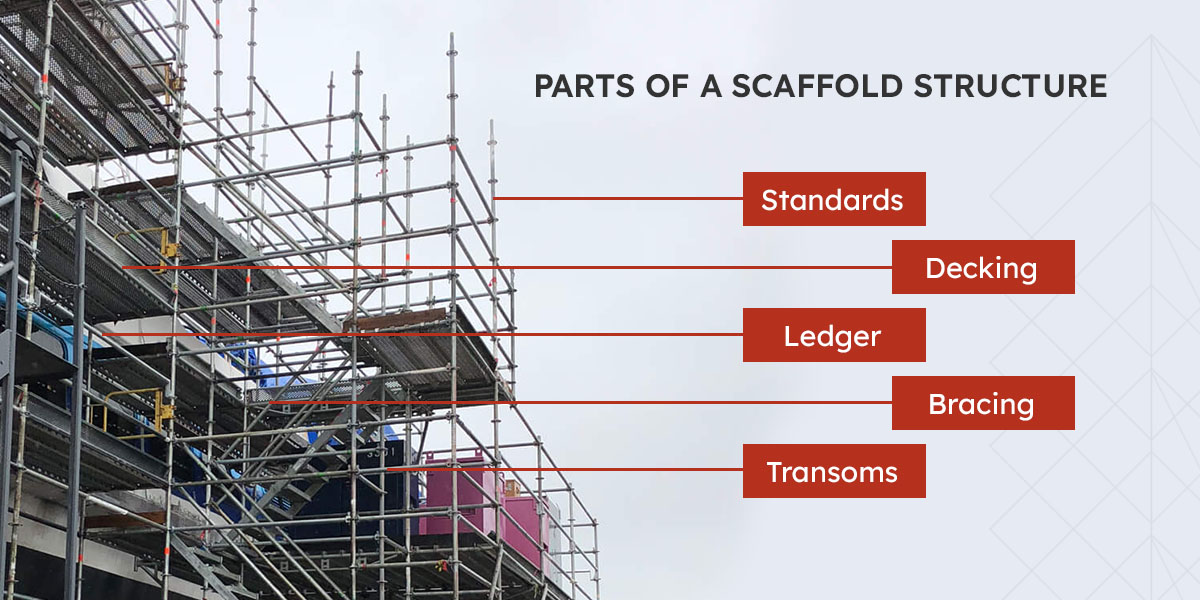

Parts of a Scaffold Structure

The following standard scaffold parts each play a significant role in elevated work platform safety:

Base Plates and Sole Plates

Base plates support a scaffold’s frame at the base of its columns. Each base plate distributes the column’s weight across a wider area to increase stability. The following types of base plates support scaffold:

- Flat

- Angle flat

- Spigot or ribbed

Sole plates prevent the scaffold from sinking into the ground. They help distribute the weight from the base plate when installing scaffold on soft or unstable ground. Sole plates are typically not necessary on solid, concrete surfaces.

Standards

A standard is the vertical tubing that connects the scaffold’s mass to the floor or ground via a base plate. Standards have fixed lengths, so multiple pipes must connect to each other in taller scaffold installations to properly route the load through the structure. Pin and socket joints twist and lock pipes together, securing them in place.

Scaffolders place pairs of standards at the front and back of a scaffold, forming a bay with length and width. This design transfers the entire structure’s weight through the base plates and sole plates to the ground. The distance between standards depends on the type of work a scaffold must support. For example, the tubes are slightly closer together if you need to complete heavy-duty work and a little farther apart if you need to perform light duties such as painting.

Ledgers

Ledgers run horizontally between standards. Ledgers are also known as cross beams or runners, and they provide extra weight distribution and support. They connect multiple bays at the front and back of a scaffold, and they have staggered joints. A scaffold’s lowest ledger is placed near the ground, but the other ledgers’ placements depend on the height of the worker platforms.

Transoms

Transoms are also known as bearers, and they define a scaffold’s bay width. A transom is a horizontal tube that spans across a ledger at a right angle. This piece holds rows of standards in place, stabilizing the structure. Transoms are essential for scaffold strength and safety.

Bracing

Bracing is another crucial part of scaffold stability and safety. The following types of bracing stiffen scaffold to prevent displacement and swaying:

- Facade: Facade braces attach to a scaffold’s front face and run along the frame’s length diagonally. Facade bracing should be installed on the first, last and every fourth bay to prevent the space between from exceeding three bays.

- Transverse or cross: Transverse or cross bracing runs diagonally between inside ledgers and attaches to outer standards via swivel couplers. This type of bracing joins outer and inner alternate standard pairs.

Working Platform

A scaffold’s working platform is the elevated surface where workers walk, stand and perform tasks. This platform must safely support the weight of workers, their tools and any equipment they use while on the scaffold. A working platform must also be able to withstand high wind loads.

Decking

Decking or platform planks are the individual boards that make up a scaffold’s working platform. They are typically made of aluminum, steel, manufactured wood or scaffold-grade sawn wood. Planks must be close together and close to the building the team will be working on to prevent falls and accidents.

Toe Boards and Debris Protection

Toe boards are crucial if workers use tools or materials on a scaffold work platform. They run along the perimeter of the scaffold work platform to prevent objects from falling and injuring workers below.

The following additional falling debris protection may be necessary in areas where workers will perform tasks in the general vicinity of the scaffold:

- Debris nets or canopy structures to catch falling objects

- Barricades to block hazardous areas beneath scaffold structures

- Screens between the working platform’s handrails and toe boards

Guardrails

A scaffold working platform’s guardrails serve as a fall protection system, preventing serious accidents and injuries. The guardrail system is installed on the working platform’s ends and open sides, and it’s mandatory for any elevated work platform that’s at least 4 feet off the ground.

Couplers

Couplers or clamps are vital fittings that connect scaffold tubes. The following types of couplers connect tubes and help stabilize scaffold:

- Swivel: Swivel couplers can connect tubes at various angles, making them highly versatile. They are ideal for angled connections such as diagonal bracing.

- Right-angle: Right-angle couplers are also known as 90-degree or double couplers. They connect tubes at a 90-degree angle to form perpendicular connections.

- Sleeve: Sleeve couplers join the ends of tubes together, extending the length of scaffold structures.

- Putlog: Putlog couplers connect ledgers to transoms, increasing support for planks or boards. This type of coupler is suitable for light-duty applications.

- Board-retaining: Board-retaining couplers prevent scaffold boards from slipping, increasing safety.

Ties

Ties connect scaffold structures to the building a team needs to work on. They prevent the scaffold from swaying and falling away from or toward the building. Ties also stabilize individual standards to prevent buckling. The heavier the load on a scaffold, the more ties it requires for stability.

Access Ladders

Scaffold access ladders enable workers to ascend and descend the structure and reach working platforms safely. An access ladder is secured to the outside of the scaffold and features a self-closing gate to separate it from the platform.

Importance of Professional Scaffold Installation

Professional scaffold installation is essential and offers the following advantages:

- Peace of mind: When you trust experienced professionals with your scaffold design and installation, you can rest assured it will support you and your work.

- Compliance: Scaffold installation experts adhere to safety standards, minimizing legal risks.

- Efficiency: Trusting professionals with your scaffold requirements saves time and money. Experts erect scaffold properly the first time, preventing mistakes, project delays and unexpected costs related to poor installation.

Rent Scaffold From Champion Scaffold Services Inc.

Scaffold requires precise components and proper installation to support people, tools and materials at elevated heights. Champion Scaffold Services rents scaffold, providing safe access solutions you can trust. Our experts understand the strict requirements for all scaffold components and ensure each installation meets industry standards.

We measure your site before each installation, providing a detailed estimate and planning the scaffold with your unique project in mind. Our design, build and inspection services ensure a safe elevated structure that meets OSHA regulations and protects each individual who uses it. We use only the highest-quality scaffold materials and are proud to serve the Greater Bay Area and its surrounding cities. Contact us to request a quote or learn more about how we can meet your needs.