If you’re a contractor, you know that scaffold is critical to almost all construction projects. These structures, typically made from durable steel or aluminum, provide a safe platform for workers as they construct or repair buildings at varying heights.

Scaffold is a temporary structure of wood planks and a series of metal poles that elevates and supports workers as they carry out construction tasks. Contractors commonly use scaffold in the following applications:

- Building new structures

- Repairing, maintaining and cleaning existing structures

- Industrial inspections

Scaffold is available in many designs to suit all kinds of construction projects. Read on to learn about scaffold types and when to use them.

What Are the Different Parts of Scaffold?

Before we discuss the types of scaffold in the construction industry, let’s get familiar with scaffold’s key components. Following is a list of the parts that make up a scaffold system:

- Standards: These vertical poles support the workers’ platform.

- Ledgers: These horizontal support poles fit between two standards, creating the length of the scaffold bay.

- Braces: These support poles attach diagonally to the standards.

- Putlogs: Putlogs connect the ledgers to the wall being worked on. Installers cut holes in the side of the structure to accept the putlogs.

- Transoms: These horizontal load-bearing poles fit beneath the planks of the workers’ platform to support them.

- Bridle: Bridles support one end of the putlog and bridge an opening in a wall.

- Boarding: Boarding is the horizontal platform that supports workers, tools and materials.

- Guard rails: Guard rails are a safety feature that keeps workers from falling off the scaffold.

- Toeboard: The toeboard is a set of putlog-supported parallel boards that offer protection at the platform level.

- Ladders: Workers use scaffold ladders to access and exit the scaffold easily.

- Scaffold wheels: Some scaffold types have wheels at the bottom to allow easy transport within the construction site.

Why Are There Different Types of Scaffold?

Different types of scaffold exist to accommodate various construction projects — not all scaffold is created equally. Contractors choose a type of scaffold based on the following:

- How much weight it will need to support

- The environment in which the project takes place

- The conditions of the ground surrounding the structure

- Specific building and labor laws

- Costs in various parts of the world

For example, aluminum scaffold is common where labor is expensive because it’s lightweight and easy to erect. In other places, labor is much more affordable, allowing construction workers to choose more expensive types of scaffold.

What Are the Different Types of Scaffolding in Construction?

You’ll typically find five main types of scaffold when working in construction:

1. Single Scaffold

Single scaffold is the most basic scaffold system. Installers put single scaffold in place by driving its standards into the ground parallel to the building’s walls. The putlogs form a bridge between the standards and the wall to create a solid platform for workers. Installers can add more support if the single-scaffold system is high enough to warrant it.

Single scaffold is also known as brick layer’s scaffold, and construction crews typically use it in brick masonry.

2. Double Scaffold

Double scaffold is so named because it utilizes two rows of worker support. The first row of scaffold is parallel to the wall, while the second row stands behind and strengthens the first.

Installers can use rakers and cross braces as additional support methods if the scaffold must reach exceptionally high. A raker is an inclined tube that rests on the ground or an adjacent structure. It acts as a kickstand, supporting the scaffold and pushing it against the building. Cross braces form a wide X to link and support scaffold frames, helping them reach total load capacity.

Instead of relying on putlogs, double scaffold is independent of the wall. It offers a way for workers to perform at height without attaching to the structure itself. Builders often use double scaffold in stone masonry because placing scaffolding directly into stone walls can be challenging.

3. Cantilever Scaffold

Cantilever scaffold is relatively easy to install and eliminates the need for unsightly frames and beams in front of a building. These setups involve inserting a series of supports called needles diagonally into the wall. Part of the needle is inside the wall, while the rest is outside to support the work platform.

Cantilever scaffold can be less stable than other kinds. Installers sometimes place a diagonal strut from the wall to the needle’s outer edge to keep the needle steady against wind or worker movement.

Construction workers use cantilever scaffold when they can’t place supports in the ground directly below the work area. This type of scaffold sees the most use in rough or weak terrain or when building the top of a wall.

4. Rolling Scaffold

Rolling or trestle scaffold consists of a platform that rests on a wheeled ladder for mobility. This type of scaffold is a slimmer system suitable for smaller jobs like painting or minor repairs or those with limited space. There are no putlogs or standards, only the moving ladders to support worker platforms. It’s easy to move when necessary, although it offers less room for workers than other types.

Painters and repair, maintenance and warehouse workers commonly opt for the mobility of rolling scaffold. It’s available in various sizes and is suitable for indoor and outdoor uses. Since it focuses on height rather than width, this type of scaffold is a great choice for higher floors and more specific, localized projects.

5. Suspended Scaffold

Suspended scaffold is a lightweight system that hangs from the roof of the building by wire, ropes or chains. This type of scaffold is fairly straightforward, consisting of a platform that hangs over the side of a building, using the roof for support. Workers use levers or electronic systems to raise and lower the scaffold.

Suspended scaffold is a good option for jobs high above the street, such as window cleaning, painting or masonry repairs.

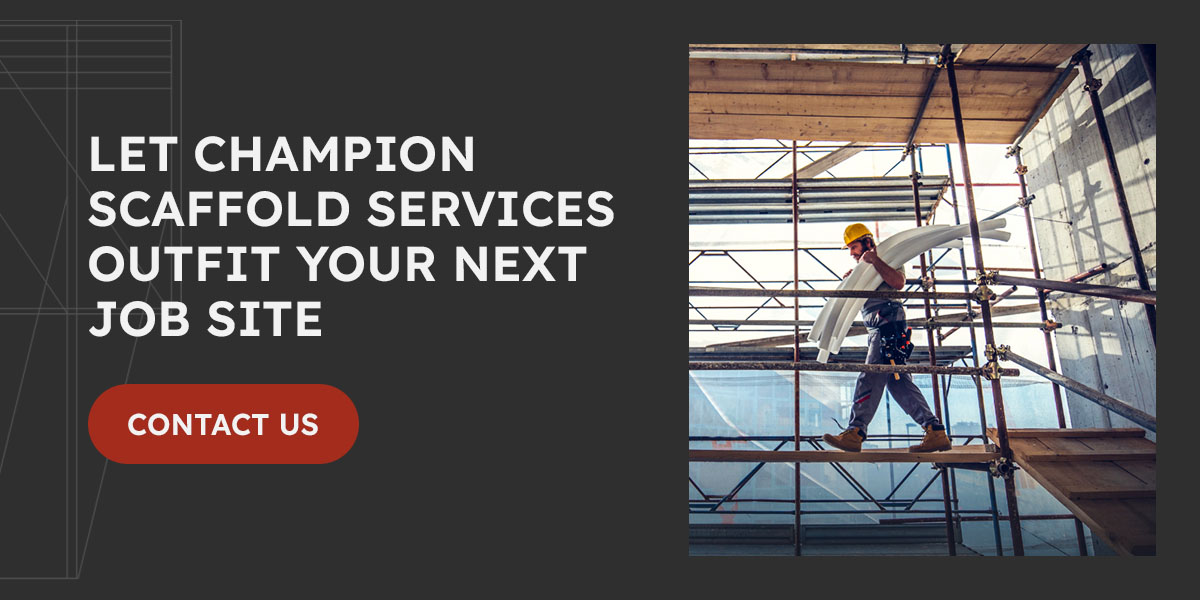

Let Champion Scaffold Services Outfit Your Next Job Site

Champion Scaffold Services is your one-stop shop when you’re preparing for a residential, commercial or industrial construction project in the Greater Bay Area. When you work with us, you’ll save time and resources shopping around for separate subcontractors. Our services cover all your scaffold needs, including installation, dismantling, shrink wrap, netting and trash chutes.

Our well-trained crews are OSHA-compliant and dedicated to safety, punctuality, a strong work ethic and attention to detail. Contact Champion Scaffold Services today for a free quote or to learn more about our offerings. We look forward to providing you with professional, knowledgeable service you can depend on!