Construction projects face constant threats from unpredictable weather, hazardous material exposure and safety risks that can derail timelines and budgets. These challenges cause costly delays, damage materials and put workers and the public at risk. Bay Area contractors need reliable protection solutions that keep projects on schedule while maintaining safe work environments.

Shrink wrap containment, including construction shrink wrap, offers a proven protective barrier using heat-applied durable plastic sheeting that shields scaffold structures, workers and materials from weather, contaminants and environmental hazards. This specialized system creates enclosed work areas that enable year-round construction capabilities while meeting Occupational Safety and Health Administration (OSHA) safety standards. For projects requiring scaffold shrink wrap in the Bay Area, the benefits are even more pronounced due to the region’s unique climate challenges.

Understanding the benefits of shrink wrap containment for construction projects helps you make informed decisions about protective solutions.

What Is Shrink Wrap Containment?

Shrink wrap containment uses durable, flame-retardant plastic sheeting applied to scaffold structures to create protective enclosures. The installation process involves applying plastic sheets across the scaffold surface and using propane heat tools to shrink the material, creating a tight, weatherproof seal that conforms to the structure’s shape. Two primary methods serve different project needs — full encapsulation and shrink wrap caps.

Full encapsulation completely encloses a scaffold structure, creating a sealed work environment. Shrink wrap caps cover only the roof or top portion for targeted overhead protection. These systems work with both modular and frame-and-brace scaffold configurations while meeting safety codes for weather protection, hazardous material containment and controlled environment creation.

Weather Protection and Environmental Control

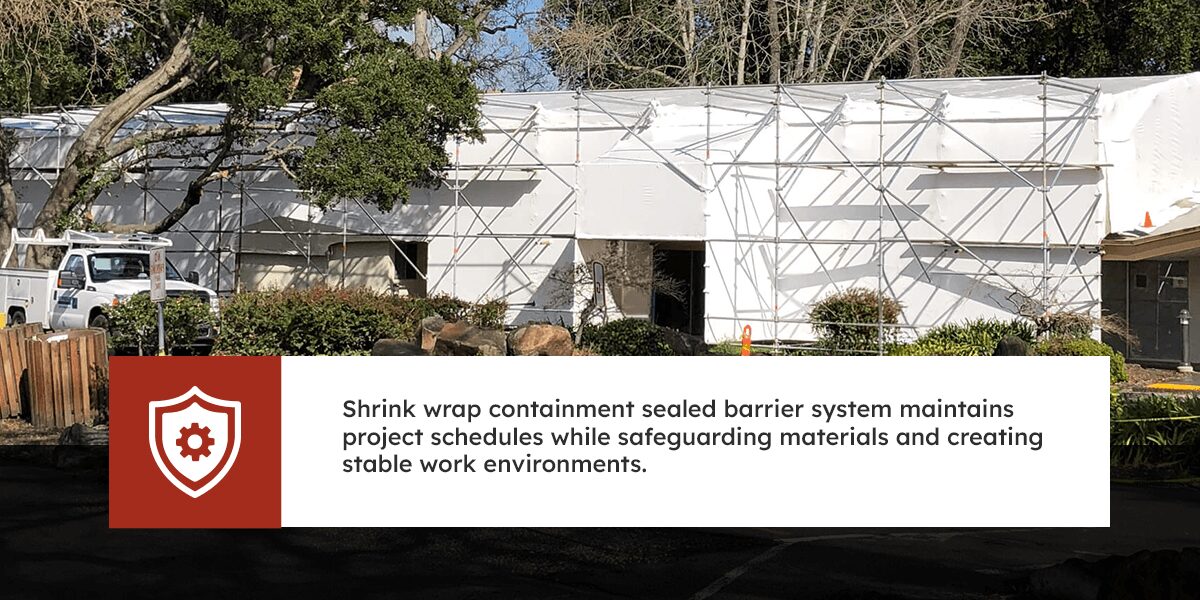

Shrink wrap containment delivers protection against the Bay Area’s unpredictable climate conditions. The sealed barrier system maintains project schedules while safeguarding materials and creating stable work environments.

Shielding Against Rain, Wind and Temperature Extremes

The Bay Area experiences unpredictable rain, wind and fog that disrupt construction schedules and damage materials. Shrink wrap creates a sealed barrier preventing moisture penetration that causes lumber warping, steel corrosion and drywall deterioration.

According to the Federal Highway Administration, heavy rain can reduce construction productivity by 3% to 16%, while heavy snow decreases work speed by 5% to 40%. These weather-related delays can translate directly into budget overruns and missed deadlines. The benefits of shrink wrap containment for construction include keeping work areas dry and protected, allowing workers to continue operations safely while materials remain in optimal condition.

Enabling Year-Round Construction Capabilities

Traditional construction often stops during adverse weather, causing project delays and cost overruns. Shrink wrap allows crews to continue working despite external conditions. The containment system can integrate heating or cooling equipment to maintain comfortable temperatures inside the enclosure.

This climate control enables precision work during weather that would otherwise halt operations. Year-round capabilities prove particularly valuable for time-sensitive commercial and industrial projects where contractors must maintain schedules and meet deadlines.

Worker Safety and Hazardous Material Containment

Protecting workers and the surrounding community remains a top priority on any construction site. Shrink wrap containment creates multiple layers of safety while ensuring regulatory compliance.

Protecting Workers from Falls and Debris

Falls remain the leading cause of death in construction. OSHA reports that 421 workers died from falls in 2023, accounting for 39% of the 1,075 total construction fatalities. Shrink wrap paired with a scaffold creates stable, enclosed work platforms that reduce wind exposure at elevated heights. The barrier helps contain falling tools and materials that could injure ground-level workers or pedestrians. Debris netting integrated with shrink wrap systems catches objects before they fall outside the work zone, safeguarding both workers inside the enclosure and people in surrounding areas.

Containing Asbestos, Lead and Dust Particles

OSHA regulations require containment during hazardous material abatement involving asbestos and lead paint. Shrink wrap encapsulation prevents airborne particles from spreading beyond the work area, protecting workers inside the enclosure while preventing community exposure to dangerous contaminants.

Renovation and demolition projects in older buildings often encounter these issues, making proper containment essential for regulatory compliance. Even on projects without hazardous materials, dust containment proves critical for air quality and respiratory health.

Durability and Material Preservation

Construction materials represent significant project investments that require protection from environmental damage. Shrink wrap containment delivers measurable cost savings through material preservation:

- Moisture protection: Prevents warping and mold in lumber, eliminating costly replacements.

- Corrosion control: Shields steel and metal from rust, maintaining structural integrity.

- Equipment safeguard: Protects sensitive machinery, like generators and power tools, from weather-related failures.

- Ready-to-use materials: Keeps materials clean and job-ready, reducing prep and cleanup time.

- Extended lifespan: Prolongs scaffold component utility on long-term projects.

- Waste reduction: Minimizes damaged inventory, supporting sustainability and cutting disposal costs.

The cost of shrink wrap containment proves far less than replacing weather-damaged inventory. Every protected component represents money saved and time preserved, translating directly into improved project profitability.

When to Use Shrink Wrap Containment

Certain construction scenarios particularly benefit from shrink wrap containment solutions. Understanding ideal applications helps contractors make informed decisions about protective systems.

Project types that require containment include:

- Hazardous material abatement projects involving asbestos or lead paint removal.

- Multistory exterior renovations needing weather protection during rainy seasons.

- High-traffic urban projects requiring dust and debris control for public safety.

- Precision work, like painting and coating, that demands controlled temperature and humidity.

- Long-term projects extending through multiple seasons.

- Sites near hospitals, schools or residential neighborhoods requiring minimal disruption.

The Bay Area’s unique climate creates specific challenges. Coastal fog and marine layer moisture require protection beyond standard tarps, while winter rainy season projects from November through March benefit substantially from weatherproof enclosures. High-rise commercial renovations in the Greater Bay Area need containment for weather protection and urban dust control. Historic building restoration and industrial facility maintenance across refineries, shipyards and power plants demand reliable protection from both weather and hazardous materials.

How Shrink Wrap Containment Works

Professional shrink wrap containment installation combines technical expertise with proven safety protocols. The process begins with a thorough site assessment and scaffold structure evaluation to analyze project requirements, including height specifications, weight considerations and environmental factors.

The shrink wrap containment installation process involves the following steps:

- Custom design: Each project begins with a tailored enclosure design to meet its specific requirements.

- On-site delivery: Professional crews efficiently deliver all necessary materials and equipment directly to your jobsite.

- Expert installation: OSHA-trained riggers meticulously install the containment system, adhering to proven safety protocols.

- Heat-shrink sealing: Propane heat tools are precisely used to shrink the plastic sheeting, creating a drum-tight, weather-resistant seal.

- Access and ventilation: Zipper doors and vents are strategically integrated to allow for controlled access and effective airflow management.

- Quality assurance: A thorough quality inspection is performed to verify the complete seal and ensure the structural integrity of the entire system.

The system integrates seamlessly with modular and frame-and-brace scaffold configurations. Installation crews coordinate shrink wrap with stairs, platforms and debris chutes for comprehensive site solutions. This integration creates cohesive work environments where all components function together efficiently.

Professional scaffold companies handle both scaffold erection and containment installation, eliminating coordination challenges between separate contractors. This streamlined approach saves time, reduces costs and ensures compatible systems.

Turn to Champion Scaffold Services Inc. for Scaffold Containment

When your construction project demands reliable protection from weather, contaminants and safety hazards, turn to Champion Scaffold Services. We partner with experts to deliver specialty shrink wrap containment services designed for your application. Since 2009, we’ve been providing Bay Area contractors and property owners with access solutions they can trust and afford. As members of the Scaffold & Access Industry Association, we bring decades of combined leadership experience to every project.

Our full-service approach means you get both scaffold and containment from a single provider — no need for additional contractors. We handle everything from initial site assessment and custom design to professional installation and final dismantling. Our OSHA-trained riggers ensure every enclosure meets safety standards while protecting your workers and the surrounding community.

Contact Champion Scaffold Services today for a free quote, or call us at 510-788-4731 to learn more. For fast emergency service, call 510-965-7086.